Guarding of legacy machinery

This bulletin arises from an incident at a manufacturing business with a sawmill in which a worker was injured while using legacy equipment. It reminds all operations that legacy equipment, while it might have been considered safe when acquired, and have been operated for decades without incident, it needs to be regularly assessed by a competent person.

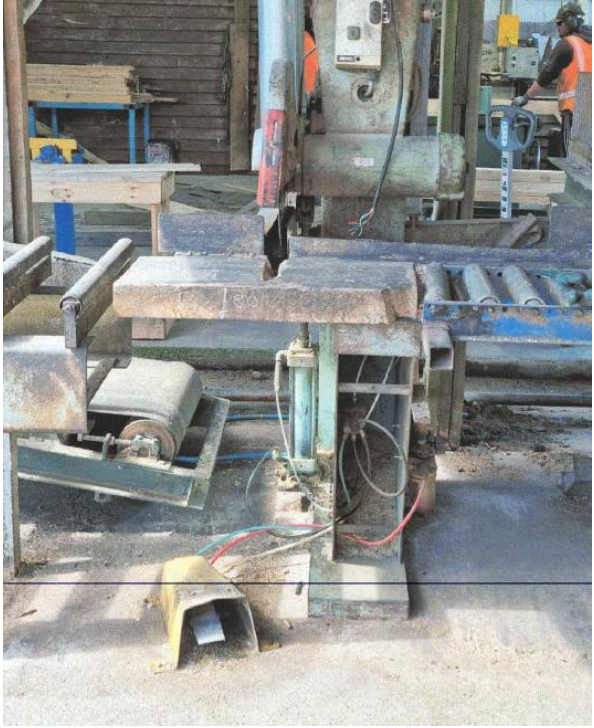

Description and picture of equipment

The equipment involved in the incident was a flicksaw used to trim ragged ends of timber as it comes out of the sawmill onto the green table for grading and sorting. It was operated by a foot pedal enclosed in a ‘boot’ cover to prevent accidental operation. When not actively cutting the saw blade retracts into a housing. Depressing the foot pedal brought the saw blade forward and down to cut the timber. The blade retracts when foot pressure is removed.

The sawmill was relocated to its current site in the 1970s and it is thought that the saw dates to that era.

The current owners purchased the sawmill in 2006 and refurbished all the equipment prior to commencing their manufacturing operation on the site in 2008. The flick saw was electrically and mechanically upgraded and a foot pedal cover was added. The basic operation of the saw remained unchanged.

The company upgraded their Health and Safety Management System over 2013-2016. The hazard list for the flicksaw was reviewed as part of this and the risks around the spinning blade were recognized. The possibility of an accidental activation of the saw was not identified. Following a routine WorkSafe visit in 2015 a nose guard over the saw was added at their recommendation, to bring the saw into compliance with the 2014 Guarding Standard [1].

Summary of incident

The incident occurred on 21 December 2021, the day before the scheduled Christmas shutdown. The only witness to the incident was the victim, who reported that he stumbled on a piece of wood, he thought it may have been the offcut from his latest cut. He put his hand on the saw bench to steady himself and somehow the saw was activated, severing two fingers from his left hand. He suggests that he may have stepped on a piece of timber, one end of which was inside the boot, resting on the foot pedal, thereby activating the saw.

This was the only known safety incident involving this saw, and the only incident of significant injury, in the company’s history.

Prime Cause

The prime cause of the incident and injury was inadequate guarding, such that the saw could be activated while the operator’s hands were within the cutting range of the saw blade. The trimming operation did not require the operator to place their hands near the blade during cuts, as the saw itself gripped the timber and held it against the back plate during the cut. The foot pedal gave the operator control over when the saw would be activated, and the boot cover was intended to prevent accidental activation. The unlikely cause of activation in this incident was not foreseen.

Action taken to remedy

The day following the incident the flicksaw was decommissioned and WorkSafe subsequently imposed a Prohibition Notice on the saw.

Over the Christmas-New Year shutdown consideration was given to WorkSafe’s approved upgrading of the guarding on the flicksaw to meet the 2024 Guarding Standard [2], but after consultation with staff in the New Year, it was decided to replace it altogether, and the flicksaw was removed. It was replaced with an upgraded Jump Saw, fully guarded to prevent hand access to the blade, as below.

The clamp function of the Jump Saw eliminates the option for the operator to hold the timber in place for the cut, and the guarding ensures operators hands are not within range of the blade during the cut. After cutting, the blade fully retracts within the housing of the machine, removing the hazard of the spinning blade when not actively cutting. The foot pedal has been reconfigured from the central placement to the side for ease of operation. A short conveyor has been included to remove the offcuts to a waste bin after cutting.

The company’s in-house Maintenance Engineer attained certification as a Certified Machinery Safety Expert (CMSE) via a week-long course and assessed coursework. This enabled him as a competent person to ensure the jumpsaw, and the other guarding upgrades the company installed, met the requirements of the 2024 Guarding Standard [2].

Learning

Despite the flicksaw having been in operation for decades without any incident, it had not been upgraded for compliance with the current Guarding Standard, and one unforeseen accident resulted in the loss of two fingers for the operator.

Following this incident the company undertook a review of all its equipment, much of which had been in use for 20+years, if not dating from the original sawmill of the 1970s.

They identified many points of inadequate guarding, many of which were readily addressed at moderate cost by the company’s in-house engineering staff, and without compromising productivity.

Upskilling their existing staff and attaining CMSE certification in-house was a valuable and cost-effective step in enhancing safety and ensuring compliance with the Guarding Standard.

The legacy equipment is still operating efficiently for the scale of the company’s operation and is now doing so with greatly enhanced worker safety. In only two cases was it deemed more economical to replace a machine rather than upgrade the guarding on the existing machine.

Where machines are still productively doing the job they were designed for, they need not be discarded merely due to the guarding standard being of an older generation. Older equipment can be productively upgraded to meet current standards of machine guarding and retained in operation. Upskilling relevant staff to CMSE competence is a valuable pathway to appropriate guarding upgrades. The costs are not prohibitive and the benefits to worker safety are immeasurable.

[1]AS/NZS Safety of Machinery series 4024.1601:2014

[2]AS/NZS Safety of Machinery series 4024.1601:2024